Mechanical & Electrical

Maintenance of mechanical and electrical systems is necessary, and managing this maintenance is frequently one of a facilities management company’s primary services.

Mechanical and electrical install and maintenance

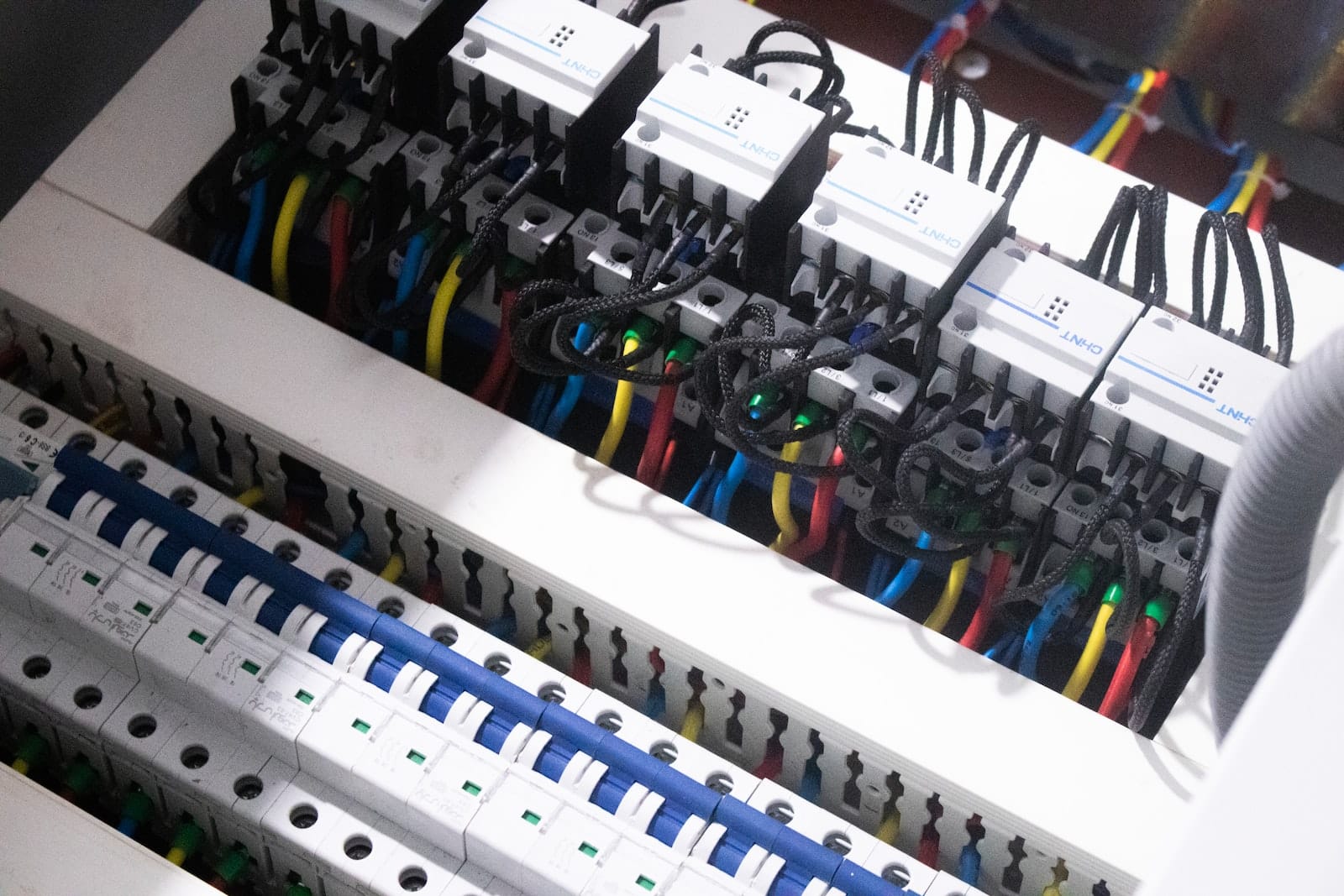

Mechanical and electrical systems are referred to as M&E, typically in the context of construction. Mechanical systems can relate to equipment and machinery, infrastructural components, tools, heating and ventilation systems, as well as both systems together because they are frequently utilised together.

Next, when discussing electrical systems, this might include power generation, transmission, and distribution, as well as computer instrumentation and control systems. Nonetheless, a lot of systems have parts from the two, which is why M&E is such a widely used phrase.

In addition to being a top facilities management company, TFM is also a specialist in mechanical and electrical maintenance.

In fact, we can maintain every service you need to ensure the safe and efficient operation of your buildings.

M&E Maintenance

Maintenance is required for both electrical and mechanical systems. Facilities management firms often manage electrical and mechanical maintenance. These services include preventive maintenance, fault finding and electrical inspection and testing. They also include portable appliance testing, gas safety, gas soundness, emergency lighting tests, life system testing, routine repairs and 24-hour emergency and reactive service. Every customer has different needs. For example, one customer might need full-time support while another may only require occasional inspections or maintenance.

M&E maintenance is an essential service that can never be disregarded if you want to work and operate your business in a safe and efficient environment.

Planned M&E maintenance is far easier to manage and significantly more effective than emergency and reactive maintenance. If a breakdown occurs, it will most likely have a greater impact on your company’s production; but, when you have planned maintenance, you may plan any downtime and carry out the repair at calmer periods, on weekends, or at night. Nevertheless, perhaps, with proper regular maintenance, you won’t require as much emergency and reactive maintenance.

Conducting regular internal health and safety inspections and audits on the mechanical and electrical components in your facilities is essential to guaranteeing that health and safety compliance standards are met.

Mechanical and Electrical Installations

Any commercial property may have mechanical and electrical installations, which should only be handled by experts. They should also be carefully planned in order to disrupt operations as little as possible while continuing to meet the needs of the business both now and in the future. Examples of mechanical and electrical installations that should be used to improve the functionality and efficiency of a commercial property include ventilation systems, cold rooms, air conditioning, refrigeration, ductwork, heating systems, and boilers. The environmental impact of these installations should be reduced while user productivity is increased.

When looking for M&E installations, it’s critical to select a professional mechanical and electrical engineering team that can handle everything from design and advice through installation, inspection, testing, and certification.

The Benefits of M&E Facilities Management

A Facility’s Management company’s responsibility for the maintenance and servicing of clients’ buildings systems and facilities, including electrical and mechanical systems, helps to improve a company’s efficiency while lowering costs. Regular checks and consultations may help to significantly reduce the risk of long-term, cumulative damage, allowing for much lower future repairs and replacement costs.

Mechanical and electrical services include the diagnosis, location, and repair of equipment, plants, and machinery. It may also entail assessing new system designs for compliance with established standards. While a general service is performed to avoid equipment malfunctions, it has no influence on the design/performance capabilities of the equipment being repaired. TFM provides all of these services at a professional and skilled level throughout the UK.